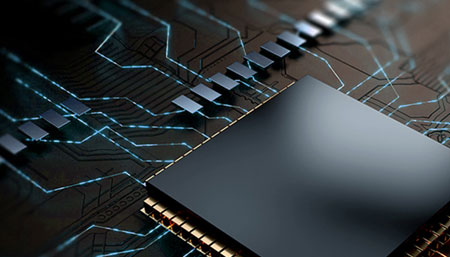

As the most important thing of the product is the circuit board, and here we came to Kiloview SMT(Surface Mounted Technology) production workshop, where we complete the board’s mounting process. Today we will take a tour to see how Kiloview products are made with the company of Thea.

Subtitle

In the begining of the video we see a circuit board of Kiloview N4 converter without components in it. In this video you will see how it is processed and finished.

The first step is brushing solder paste, which is a thick paste-like soldering material, and then it is matched with a steel sheet full of holes corresponding to the soldering position. The machine will use a scraper to evenly scrape the solder paste to the position to be soldered. By now we have completed the first step – brushing solder paste.

At the second step, this machine is used to detect the quality of the solder paste. Half of the products may fail in this process, so passing the test of the machine means that the printing quality is okay.

The third step comes to the mounting machine, whose main function is to catch all kinds of small components, and then accurately install them to the corresponding position on the circuit board. We have more than 1,000 components on a circuit board, and we need a mounting machine to install at a very high speed. This machine can install thousands of components per hour at the fastest.

The fourth step comes to reflow soldering, which is actually a long strip furnace with different temperatures. The mounted circuit board, go in from here, after heating up, soldering, and cooling in this furnace for several intervals, the solder paste previously brushed on it will solidify into solder, and the components will be firmly soldered to the circuit on the board.

The welded board will be inspected in this AOI Optical Detector for welding quality in case dropped components, welding deviation, and virtual welding to ensure the quality of our products.

Connector soldered, a circuit board is processed.